-

DATA

2021/07

-

CLIENT

-

PROJECT NAME

WHAT’S KNIT?

PLANNING & CREATIVE DIRECTION & DESIGN ( SPACE / VISUAL / One of the works )

TAKT PROJECT

COPY WRITING & PLANNING ASSOCIATE

PHOTO

Masaki Ogawa ※Except experimental photos.

VIDEO

Planning : TAKT PROJECT Production : Kenichi Hashimoto

LINK

Collaborate

Cultivating new possibilities of technology.

KANEMASA KNITTING Co., Ltd. was established in Wakayama City, Wakayama Prefecture, in 1964. Specializing in circular knitting, KANEMASA KNITTING is the only company that can produce ultra-fine high gauge jacquard fabric called super fine gauge. The company has been producing the knit fabric for apparel brands, but the momentum to launch its own consumer brand has been growing.

With the company's technology, it is possible to develop high quality products that are in line with existing values. In seeking a unique identity, however, what new possibilities could be awakened using the technology? As a starting point for the launch of its brand, we decided to explore the possibilities of the technology rather than the product design.

We believe that a special technology like their superfine gauge can awaken the imaginative power of creators. We invited creatives with diverse backgrounds and perspectives to investigate the potential of advanced circular knitting technology, and to present the results in the form of an exhibition.

TAKT PROJECT took part in the project planning, exhibition curation, and creative direction, and also designed a work for the exhibition as a creator.

563699964' WHAT’S KNIT? - This is a knit. That is a knit, too '

Many people might think of a winter sweater when encountering the word “knit.” However, knit fabrics are in fact used for many types of underwear, sportswear, and T-shirts as well. Knit fabrics are natural, highly elastic, less prone to wrinkles, and nicely fit to the body. This functional material is used everywhere, and there are even more virtues. Kanemasa Knitting Co., Ltd. has constantly been pursuing the cutting-edge circular knitting technology for 57 years, since its establishment in Wakayama City, Wakayama Prefecture. In this exhibition, Kanemasa, in collaboration with five creator groups with diverse backgrounds, presents the potential of technologies which the company has been exploring. There is an unknown profundity of knit fabrics that can only be seen by knowing more about them. We hope this exhibition will provide an opportunity to rediscover knit fabrics.

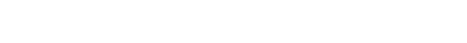

FROTTAGE / Yusuke Oono ( DOMINO ARCHITECTS )

Drawing on a material known as “laminated panel,” produced by applying metal or resin to wood, this Frottage series is a “knit laminated panel” made by covering a soft, elastic knit over wood. The combination of the wood panel—treated with uzukuri to emphasize the grain―and a “46-gauge double-faced knit”―which has a fine, high-gauge structure―allows the fabric to naturally follow the unevenness of the wood grain, creating an exquisite pattern. With its rich variation in texture, I expect the material to be used for interiors and furniture.

Textile direction : TEXT

Production : studio arché

mist / Shiori Ono

This work is at once a string, a cloth, and a garment. The production process started with the development of a delicate, translucent material that resembles ultra-thin washi paper. Using polyester monofilament yarn, the thinnest yarn that can be machine-knitted, and post-processing it, I created a mist-like textured fabric. By unraveling one of the 72 threads and manually knitting the thread back onto the fabric, mechanical and hand-made textures were given to a single surface. The result is a piece of clothing with a variety of expressions.

CFCL003 / Yusuke Takahashi

Circular-knit fabric is tubular in form and generally cut before use. However, this work uses an uncut tubular knit fabric that consists of three parts: white, black, and a combination of white and black. All three pieces shown here have the same woven pattern, but a pattern emerges in only the white and black dresses. In order to convey the appeal of high-gauge jacquard, which can create a variety of patterns if knitted differently, I created a continuous knit with 10 types of woven patterns. For this project, as well as in my own brand CFCL, I tried to minimize waste in the production process and mainly used recycled fibers. This time, I used GRS-certified recycled polyester derived from plastic bottles.

Nen dot/wave/geometry / Yuri Himuro

As a textile designer specializing in weaving, I focused on the structural difference between woven and knitted fabrics. Woven fabrics hardly expand or contract when pulled vertically or horizontally, but knitted fabrics have a soft and flexible structure; therefore, the latter produces dynamic forms without the help of special chemical fibers.

For this project, I used high-twist yarn―cotton yarn that is twisted with force in one direction. I created the work through the experiment to find how far a three-dimensional form is achievable with only natural fibers. The title “Nen” comes from the word “twisted” in Japanese. With the delicate unevenness and translucency of the high-gauge knit, the work explores the nuances of light and shadow in fabric.

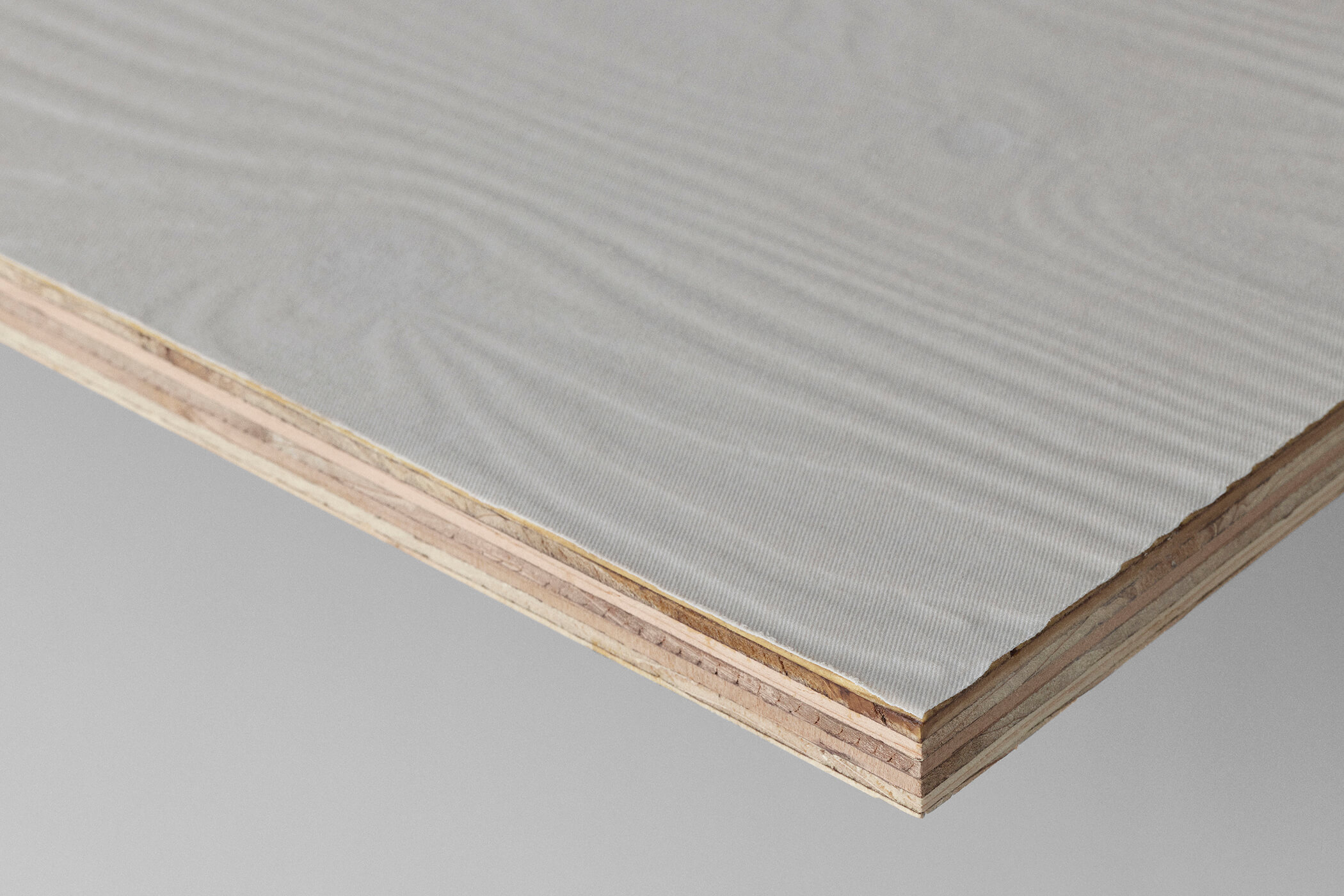

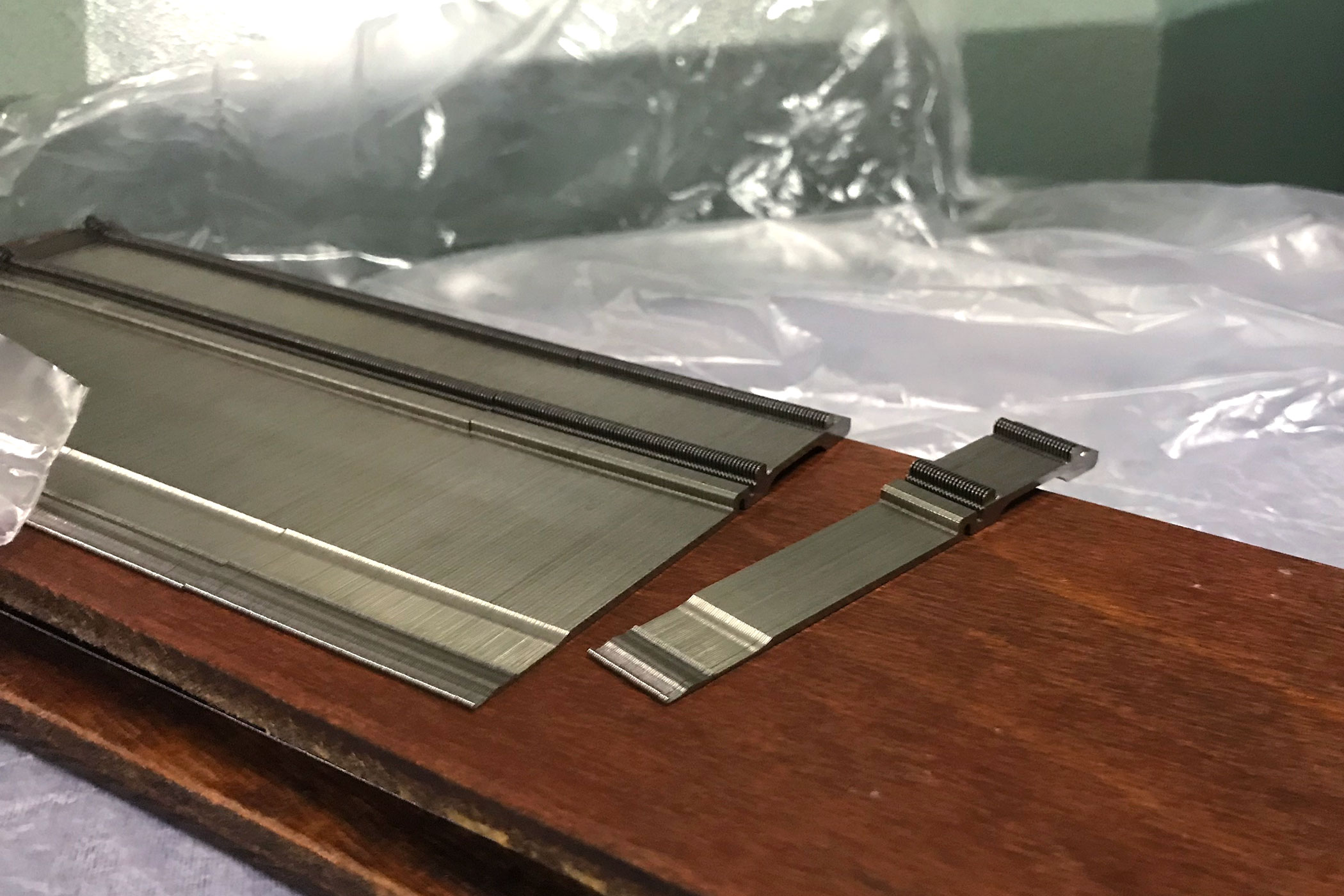

Equilibrium Flower / TAKT PROJECT

A soft knit fabric stands on its own, just barely balanced.

This form was created by developing a special thermally hardening fabric knitted with a fusible bonding yarn that shrinks when heated. When a metal frame is pressed against the fabric and heats it partially, the fabric shrinks and hardens along the frame, while the unheated part remains soft. Within the work, therefore, the soft texture characteristic of textiles and the rigid, structural support coexist. The balance between the cloth trying to outspread and the hardened supporting structure somehow evokes the vitality of a bud on the verge of flowering and the state of equilibrium with the outside world. This work has a soft but intense presence, just like a bud about to bloom.

Equilibrium Flower